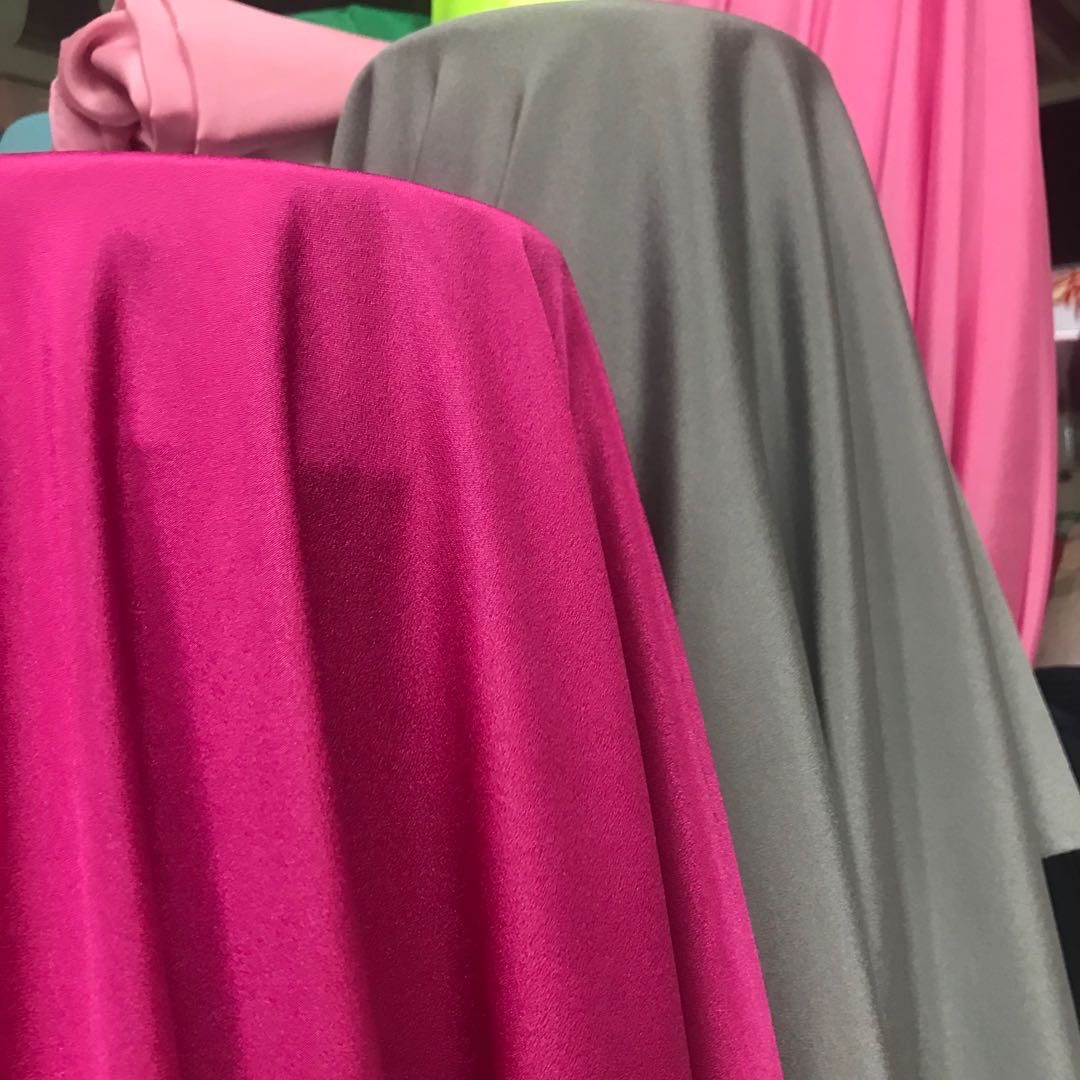

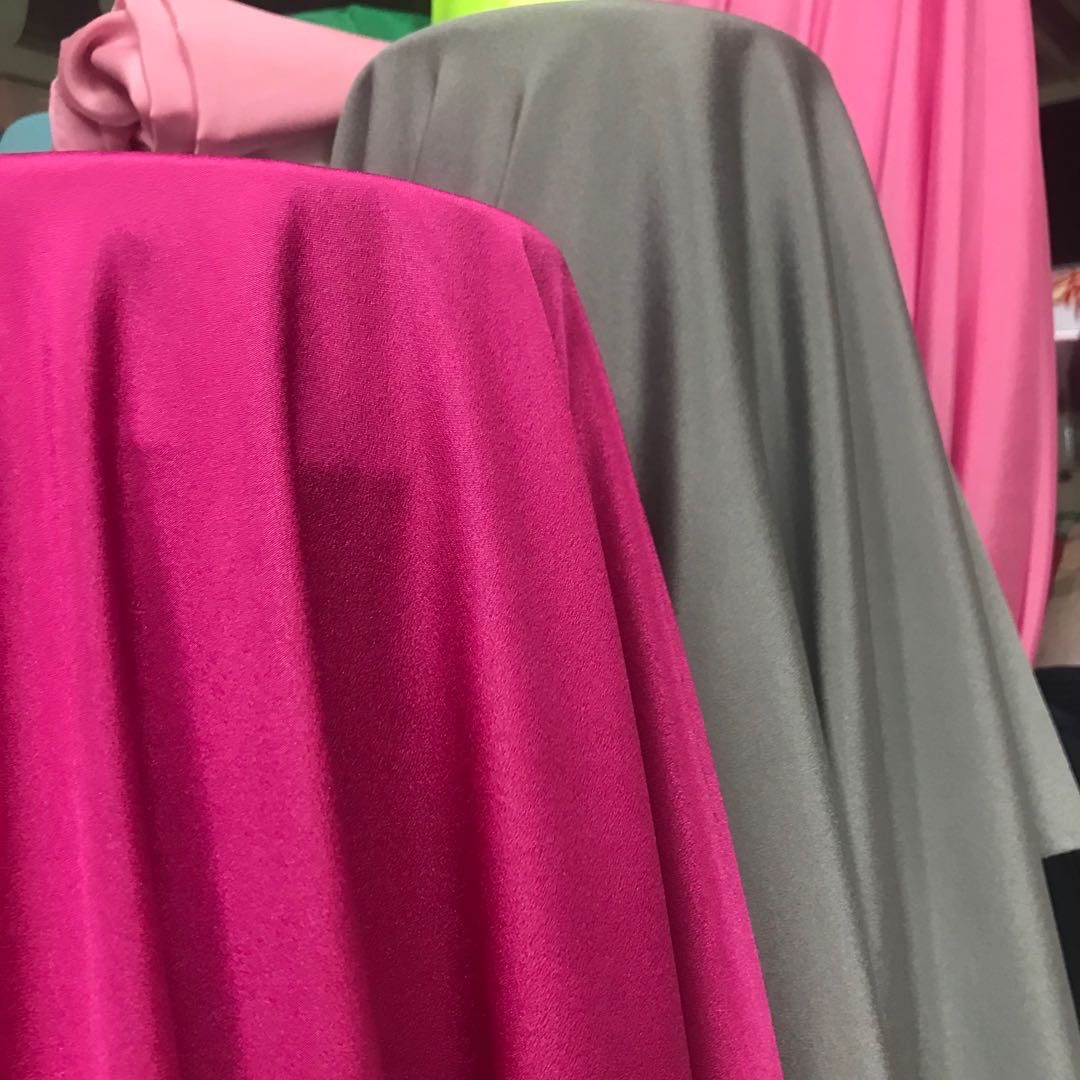

new inspiration in spring | interpretation of how high elastic crepe slightly elastic chiffon reshapes the charm of women's clothing

The spring breeze is blowing across my face and my clothes are fluttering. The focus of this season's trend has quietly shifted to a new type of fabric that can show both soft temperament and comfort-high elastic crepe slightly elastic chiffon. It not only breaks the limitations of the traditional chiffon stiff and elastic, but also perfectly combines smart and elegant with ease of stretching, setting off a wave of "light revolution" in the fashion circle.

Touch like a poem | Uncover the design code behind the lightness

This innovative fabric is not a simple physical improvement, but a redefinition of the wearing experience from the source. The delicate crepe texture brings looming luster changes, giving the clothes a unique visual layering sense. At the same time, it has the characteristics of horizontal and vertical extensibility so that it can conform to the free relaxation of body movements, and will not feel tight and uncomfortable even if it moves violently. More importantly, its internal organizational structure is like countless miniature ventilation holes, which makes the air circulation more smooth and efficient, and bid farewell to the hot and humid summer troubles. Whether it is a neat cut hip skirt or a fluffy and romantic large swing design, this material can show just the right degree of stiffness and flow. After special antibacterial desensitization treatment, the surface layer is more intimate care of every inch of skin, especially suitable for baby-like delicate physique people to buy with confidence.

Wearing a magician | a secret weapon sought after from the runway to the streets

Whether it's a holiday-style printed maxi dress or a short urban commuter suit or even a delicate waistcoat ...... Designers are constantly exploring the possibilities of this fabric. The measured data show that the clothing made of this material shows a stronger dynamic aesthetic feeling in outdoor activity scenes. when walking, the skirt is flying and the arc is naturally stopped, and the folds recover quickly and almost no ironing is required. this undoubtedly greatly improves the actual utilization rate of the single product and enables every woman wearing it to move freely and sparkly like clouds in this vibrant season

Behind-the-scenes hero file decryption | Why is it the optimal solution for garment lining

| Contrast dimension | Plain polyester interlining | High elastic crepe slightly elastic chiffon |

|---|---|---|

| Fit test | It is easy to produce friction noise and slide with the movement dislocation | Follow the body curve closely and synchronously retract and unwind freely |

| Respiratory test | The inner humidity rises to 47% after wearing for half an hour | Under the same conditions, only about 18% more environment interaction is smooth |

| Durability assessment | The service life decreases significantly after 50 bending simulations | Extreme Bending Over 300 Times Still Maintaining Complete Form |

| Color fastness rating | Slight color fading after washing for three times | The color of the five rounds of high temperature soaping is still as bright as ever |

original brand actual combat sharing | those brand stories changed by a piece of cloth

"At first, we only came into contact with this improved chiffon in order to try to improve the skin penetration problem of the summer series. I didn't expect that the feedback from the fitting was far beyond expectations-many customers said that this was the clothes they wore with the least sense of presence but the most convincing shape. So we changed the whole autumn and winter preview sample to the same type of auxiliary materials and even some exterior styles began to introduce this core element. Driving Force"-An Excerpt from an Interview with the Founder of an Independent Designer Brand

Green Commitment | Update on R & D for Sustainable Textiles

Responding to the industry's call for low-carbon while always adhering to the principle of quality first. At present, the content of bio-based fibers has reached more than 60% of the total amount of fabrics and has realized the whole process without affecting the original performance. The corner wastes generated in the production process of zero heavy metal additives can be converted into household fillers or other functional fabric raw materials through designated recycling channels to form a complete circular economy chain. The more exciting news is that the seawater degradation technology successfully verified in the recent laboratory stage is expected to enter the mass production preparation period in the next fiscal year. This means that this dress in your hand will soon have a real 'end of life' care attribute